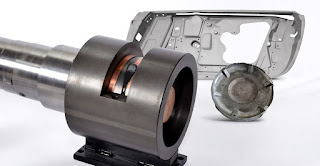

Die Cast Tooling Moldings and Cavities

Die cast tooling refers to the molds and dies which have been employed in the process. Die forged tooling is also generally known as die solid dies, insert dies, or die cast moldings, and they are offered in one cavities or a number of cavities. Solitary cavity tooling may be used to produce just one aspect at a time, whilst the a number of cavity tooling can be used to create far more than a single aspect for each cycle. The tooling expenses may vary with all the sorts of tooling. It may cost as minor for a handful of hundred dollars when trim dies are applied, but can visit a couple thousand pounds when cavity inserts are utilized. Even so, for giant and total die cast device offers, the costs can go as much as a number of thousand pounds. Die Cast Tooling Each die developed using the newest CAD/CAM computer software and that is networked directly with our CNC machining equipment to offer a seamless movement of data, precision, and repeatability. Models are based on severa